The power supply chip can be said to be the power supply heart of all electronic devices, controlling the pulse power of electronic devices, thus performing functions such as power conversion, distribution and detection.So what are the methods used in chip failure analysis?

Chip failure means that the size, shape, or material structure and performance of the chip change for some reason, so that the specified function cannot be perfectly performed. Chip failure analysis can judge the nature of chip failure and analyze the cause of chip failure. It is a technical work to study the preventive measures of chip failure. Studying chip failure can play a very important role, such as improving the quality of the chip and improving the production plan. Through chip failure analysis, it is possible to find out device defects or abnormal parameters in a very timely manner, trace the source of the problem, and fundamentally prevent quality crises in the chip industry.

There are many ways to detect chip failure, such as external visual inspection, x-ray inspection, acoustic scanning, and SEM inspection after unsealing. The external visual inspection method is to observe the chip externally to judge whether there are any abnormal phenomena such as cracks and damage on the appearance of the chip, and perform x-ray inspection on the chip, and use X-rays to see through the inside of the chip through non-destructive means to detect its chip The packaging situation can determine whether there are various defects inside the chip package, such as delamination, dislocation and fracture of bonding wires, and bursting.

The chip acoustic scanning method is to use the characteristics of ultrasonic reflection and transmission to judge whether there are impurity particles in the lattice structure of the material inside the device, and can effectively find whether there are cracks in the device, as well as abnormal conditions such as pores and delamination inside the chip packaging material. . Chip unsealing is actually a destructive detection method, but the advantage is that it can peel off the external chip and observe the internal structure of the chip after sealing.

All in all, the above are common methods for chip failure analysis.

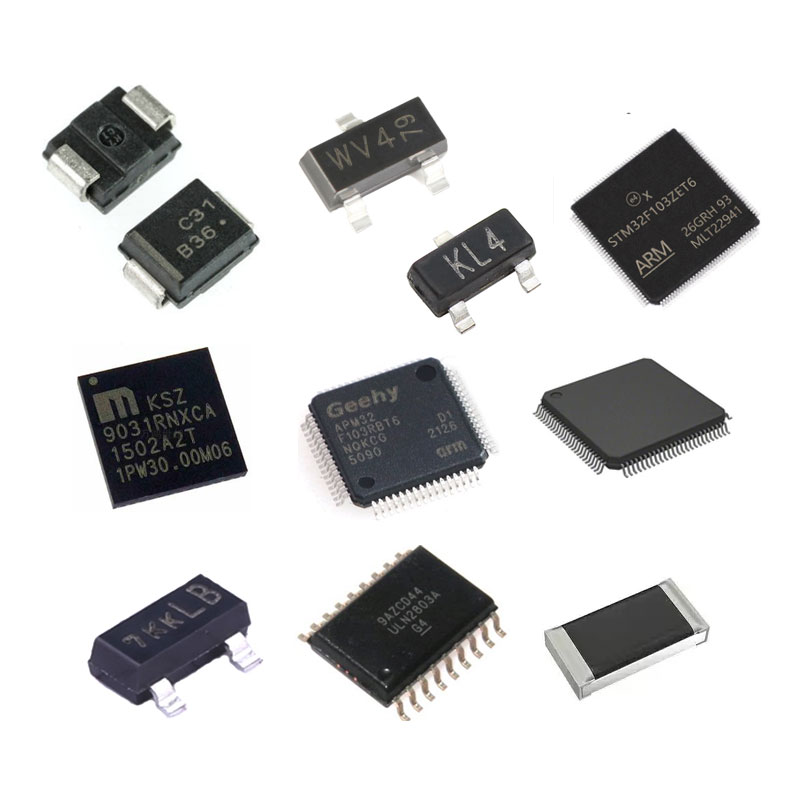

Eurotech is a worldwide supplier and exporter of electronic components, specializing in ICs, LCDs, Memory, Chips, computer parts, networking equipments and other passive components.

Tel: (86) 755 8395 9469

E-mail: info@eurotech-ic.com